The 7140-8140 Vacuum Relief Valve are designed for use on atmospheric and low pressure storage tanks,vents to atmosphere or pipe away. The primary function is to protects tanks from damager deformation, and minimizes emissions to the environment as well as loss of product due to evaporation.

Model

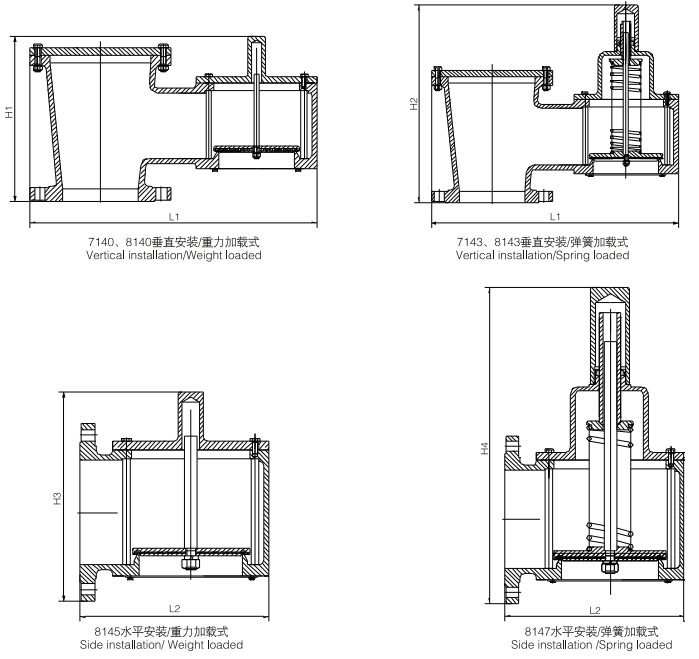

7140、8140 Vertical installation/Weight loaded

7143、8143 Vertical installation/Spring loaded

8145 Side installation/ Weight loaded

8147 Side installation /Spring loaded

Design Features

Sizes available 2″~14″(DN50~DN350);

Vertical /Side installation;

Protective screens are provided at pressure and vacuum ports to prevent entrance of foreign matter;

Flame Arrester、Inlet Pipe、Steam Jacket、Blowing Hole、Lining or Humidity Absorber are options to client;

Designed and tested according to API 2000;

The flanges are accordance with ANSI B16.5,or EN1092、JIS;

Available Materials:Aluminum、Carbon Steel、Stainless Steel、Special Materials on Application;

Setting Pressure/Vacuum

Setting KPa

|

7140、8140

|

7146、8146

|

7145、8145

|

7148、8148

|

Set pressure

|

0.2~6.9

|

0.2~6.9

|

6.9~103.4

|

6.9~103.4

|

8140、8143、8145、8147 Dimensions, mm

Nominal Size

|

L1

|

L2

|

H1

|

H2

|

H3

|

H4

|

W8140

|

W8146

|

2″(DN50)

|

300

|

-

|

180

|

292

|

-

|

-

|

155

|

-

|

3″(DN80)

|

378

|

215

|

217

|

300

|

214

|

296

|

200

|

200

|

4″(DN100)

|

443

|

241

|

253

|

361

|

252

|

361

|

235

|

230

|

6″(DN150)

|

575

|

281

|

311

|

448

|

289

|

448

|

300

|

280

|

8″(DN200)

|

705

|

366

|

370

|

615

|

350

|

645

|

360

|

345

|

10″(DN250)

|

825

|

453

|

439

|

705

|

440

|

742

|

410

|

406

|

12″(DN300)

|

970

|

525

|

519

|

853

|

520

|

909

|

470

|

483

|

14″(DN350)

|

-

|

616

|

-

|

-

|

535

|

910

|

-

|

533

|